The Laboratory of All-Solid-State Light Sources, founded in 2005, conducts the research on all-solid-state lasers and their applications. The lab focuses on fundamental and applied research work, mainly in the areas of high power all-solid-state lasers, high beam quality Q-switched and mode-locked lasers, single-frequency lasers, nonlinear optical frequency conversion and industrial applications of high power all-solid-state lasers. In recent years, based on strong scientific research ability, the laboratory has met the needs of industrial applications, developing a series of laser products which are widely used in laser welding, cutting, surface treatment, precision processing, laser medicine and in other fields.

The lab has undertaken many important scientific research projects, including National “863” and “973” research projects, and projects supported by the Chinese Academy of Sciences. The lab has taken the lead in developing 3 kW, 6 kW, 8 kW and 10 kW high power all-solid-state lasers. It maintains close collaboration with many domestic and overseas universities and research institutes.

The lab consists of excellent academic leaders and a team with strong scientific research and innovation abilities, including 2 professors, 2 associate professors, 34 assistant researchers, technical support staff and managers, and 8 graduate students.

Research direction

High Power, High Beam Quality All-Solid-State Laser Technology

High Power Single-Frequency All-Solid-State Lasers

High Power, High Brightness Short Pulse Lasers

High Energy, Low Repetition Rate Ultrashort Pulse Mode-Locked Lasers

Nonlinear Frequency Conversion Technology of High Power Lasers

Applications of High Power All-Solid-State Lasers.

Research Equipment

The lab has 60 imported sets of high precision laser drivers and test equipment, including high power LD driver sources, spot analyzers, beam quality analyzers, LASCAD optical design software, spectrometers, Hartmann sensor, GHz oscilloscopes, Ultraviolet visible infrared spectrophotometers, Optical profiler, Fiber optic taper rollers, Digital microscopes, Acoustic microscopes, Autocorrelators.

1 5 kW high power all-solid-state laser

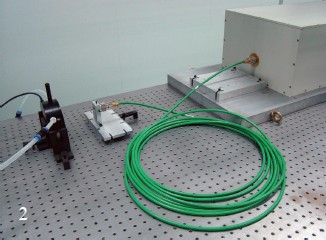

2 3kW fiber-coupled all-solid-state laser

3,4 Laser cleaning of de-painting

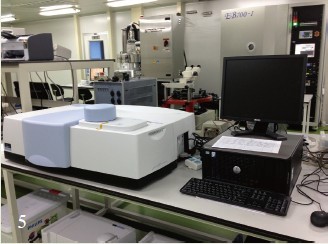

5 Ultraviolet visible infrared spectrophotometer

6 Optical profiler

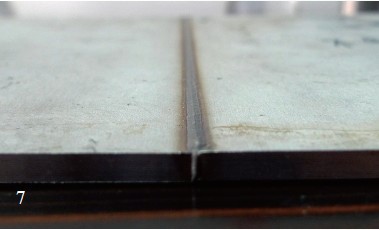

7 Butt welding of 5 mm stainless steel sheets

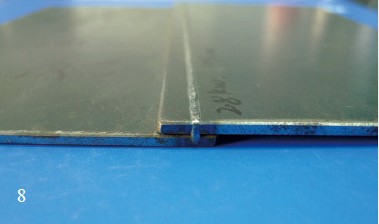

8 Lap welding of 3 mm mild steel sheets

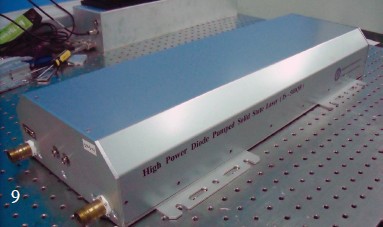

9 0.5 MW high peak power ns laser

10 100 W green laser

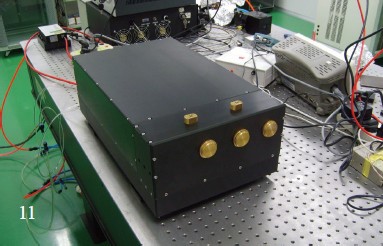

11 355 nm UV laser